usine d'ornements de Noël en résine DIY

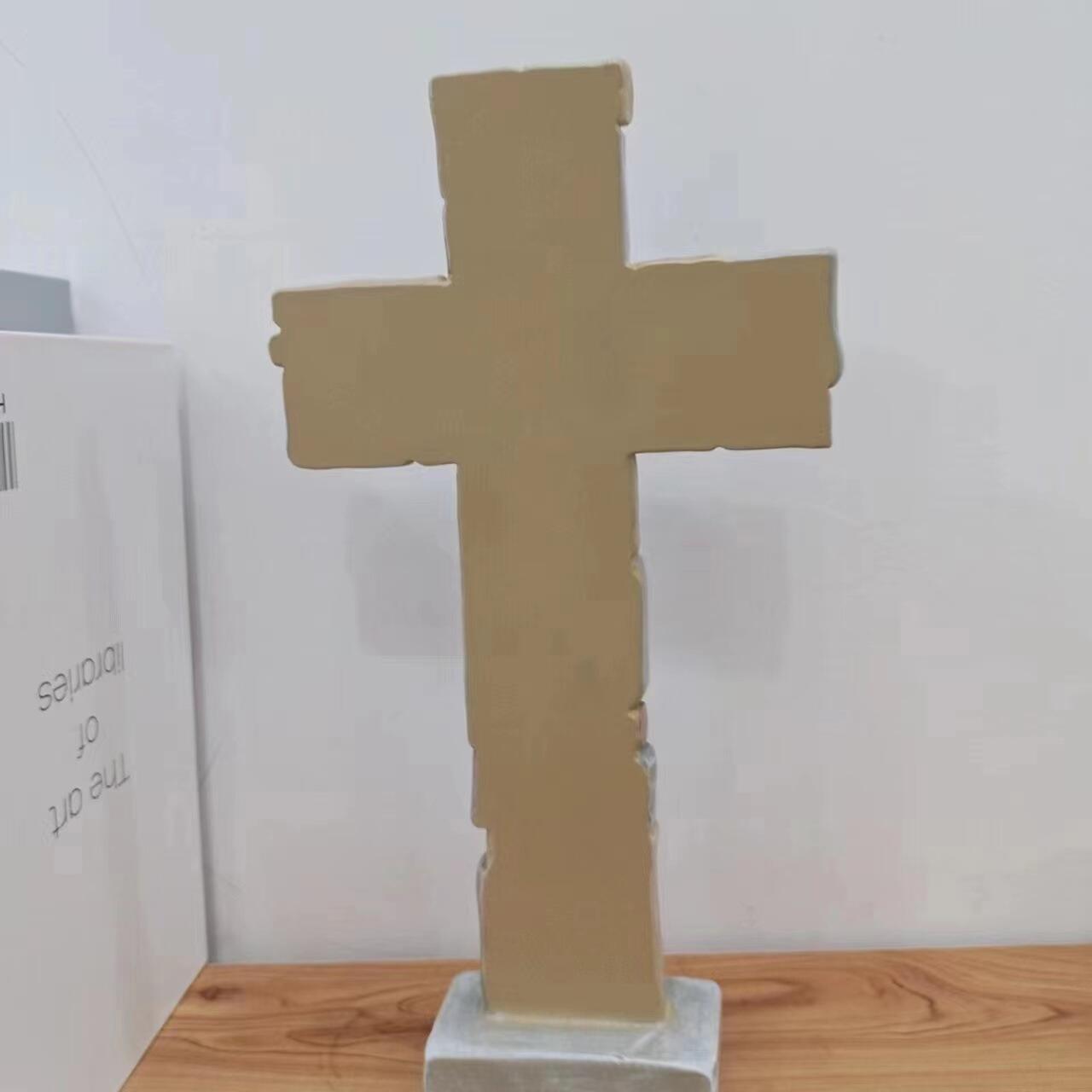

Une usine d'ornements de Noël en résine DIY représente une approche révolutionnaire de la fabrication de décorations de fêtes, combinant artisanat traditionnel et techniques de production modernes pour créer des ornements de Noël personnalisés impressionnants. Ce site spécialisé se concentre sur la production d'articles décoratifs de haute qualité à base de résine, permettant aux clients de personnaliser et de créer leurs propres décorations de fête uniques. L'usine d'ornements de Noël en résine DIY fonctionne comme un centre de production complet équipé de systèmes de moulage avancés, de matériel de coulage de précision et de mécanismes de contrôle qualité spécialement conçus pour la fabrication d'ornements en résine. Les principales fonctions de ce site incluent le traitement des matières premières, la préparation des moules, les opérations de coulage, les procédés de durcissement, les traitements de finition et les tests d'assurance qualité. L'usine utilise des formulations de résine époxy à la pointe de la technologie qui offrent une clarté exceptionnelle, une grande durabilité et une excellente fixation des couleurs, des propriétés essentielles pour la création d'ornements de Noël haut de gamme. Les caractéristiques technologiques comprennent des systèmes de mélange automatisés garantissant des rapports de résine constants, des chambres de durcissement à température contrôlée qui optimisent les processus de durcissement, et des équipements de moulage par injection de précision assurant une épaisseur uniforme et une qualité de surface constante sur tous les produits. Le site intègre des systèmes de ventilation avancés afin de maintenir des conditions de travail sécurisées lors de la manipulation des matériaux en résine, ainsi que des équipements de surveillance sophistiqués qui suivent en temps réel les paramètres de production. Les applications de l'usine d'ornements de Noël en résine DIY vont au-delà de la simple production d'ornements pour inclure des pièces commémoratives personnalisées, des articles cadeaux sur mesure, des supports promotionnels d'entreprise et des éléments décoratifs spéciaux destinés à diverses célébrations. L'usine dessert plusieurs segments de marché, notamment les consommateurs individuels à la recherche de décorations de fêtes uniques, les détaillants en loisirs créatifs ayant besoin de fournitures d'ornements en gros, les établissements éducatifs réalisant des projets artistiques, et les entreprises développant des marchandises saisonnières marquées. Les capacités de production englobent divers styles d'ornements tels que les boules traditionnelles, les flocons de neige, les étoiles, les anges et des formes personnalisées adaptées aux besoins spécifiques des clients, tous fabriqués à partir de matériaux en résine premium qui garantissent une beauté durable et une intégrité structurelle.