usine de fabrication de polyrésine

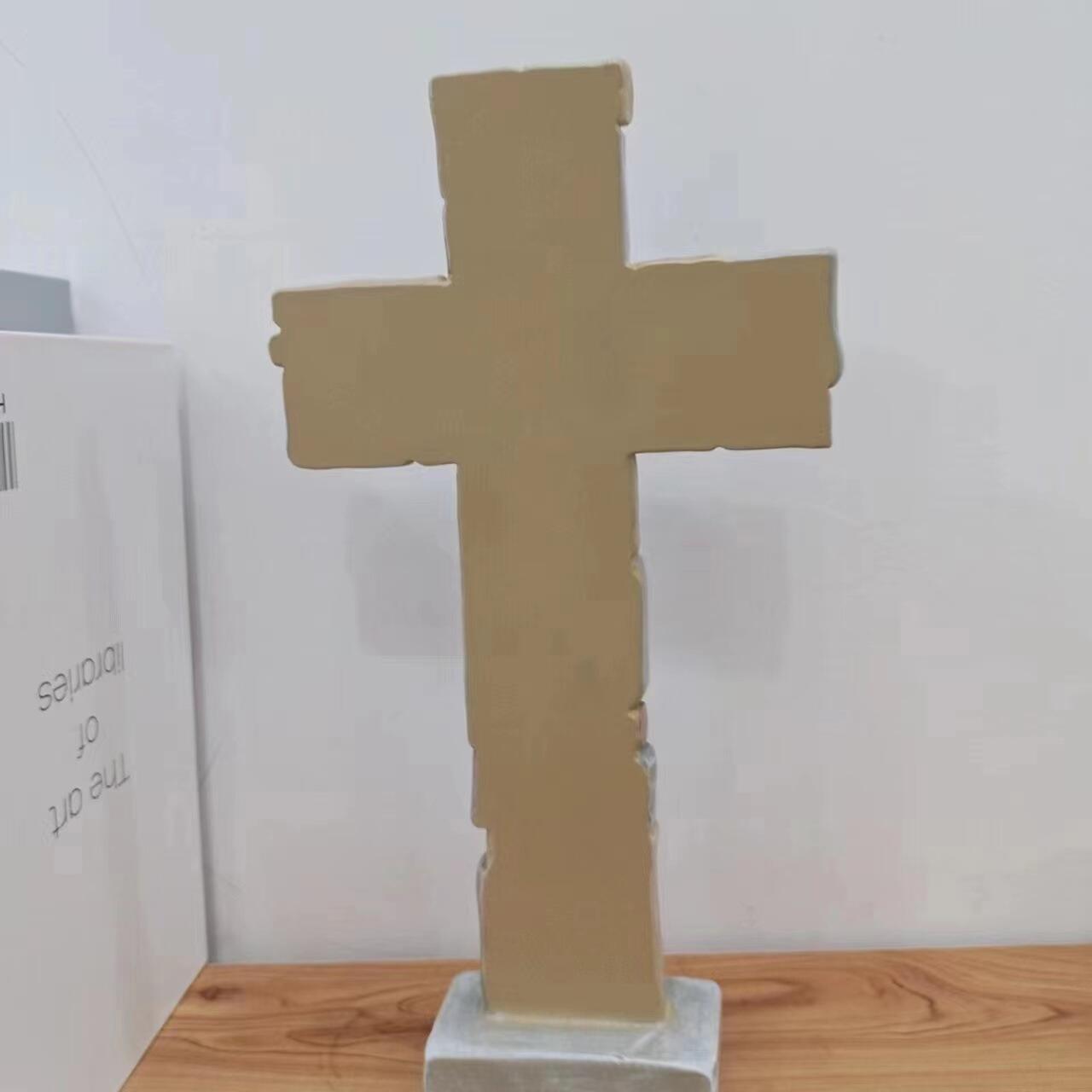

Une usine d'articles en polyrésine représente un centre de fabrication sophistiqué dédié à la production d'objets décoratifs, de collections et d'œuvres artistiques de haute qualité à l'aide de matériaux en polyrésine. Ces centres de production spécialisés combinent des techniques de moulage avancées et un savoir-faire artisanal pour créer des gammes de produits variées, allant des figurines et décorations intérieures à des articles promotionnels sur mesure. L'usine d'articles en polyrésine fonctionne grâce à plusieurs départements intégrés, notamment la conception, le moulage, le coulage, la finition et le contrôle qualité, chacun contribuant à une production fluide d'articles durables et esthétiquement attrayants. La technologie principale repose sur des systèmes de moulage par injection de précision qui garantissent des dimensions constantes et une qualité de surface homogène. Les installations modernes d'usines d'articles en polyrésine intègrent des systèmes informatisés de mélange permettant de combiner des composés de polyrésine avec des pigments, des charges et des additifs afin d'obtenir des propriétés matérielles spécifiques. Le processus de fabrication commence par une conception détaillée du produit et le développement d'un prototype, suivi de la création du moule à l'aide d'acier ou d'aluminium de haute qualité. Le département de coulage utilise des équipements automatisés de distribution pour injecter la polyrésine dans les moules sous des conditions contrôlées de température et de pression. Après polymérisation, les produits subissent des procédés complets de finition comprenant ponçage, peinture et retouches manuelles minutieuses effectuées par des artisans qualifiés. Les protocoles d'assurance qualité garantissent que chaque article répond à des normes rigoureuses en matière de précision dimensionnelle, de finition de surface et de régularité des couleurs. L'usine d'articles en polyrésine dessert plusieurs segments de marché, notamment les industries de cadeaux et souvenirs, les détaillants en décoration intérieure, les fabricants de collections et les entreprises de produits promotionnels personnalisés. Les applications s'étendent aux éléments architecturaux, aux ornements de jardin, aux objets religieux et aux marchandises liées au divertissement. La polyvalence des matériaux en polyrésine permet de produire des articles aux détails complexes, aux multiples couleurs et aux différentes textures, difficiles à réaliser avec des matériaux traditionnels. Les considérations environnementales poussent de nombreuses usines d'articles en polyrésine à mettre en œuvre des pratiques durables incluant la réduction des déchets, des procédés écoénergétiques et des solutions d'emballage recyclables.