cosas para hacer en la fábrica de resina

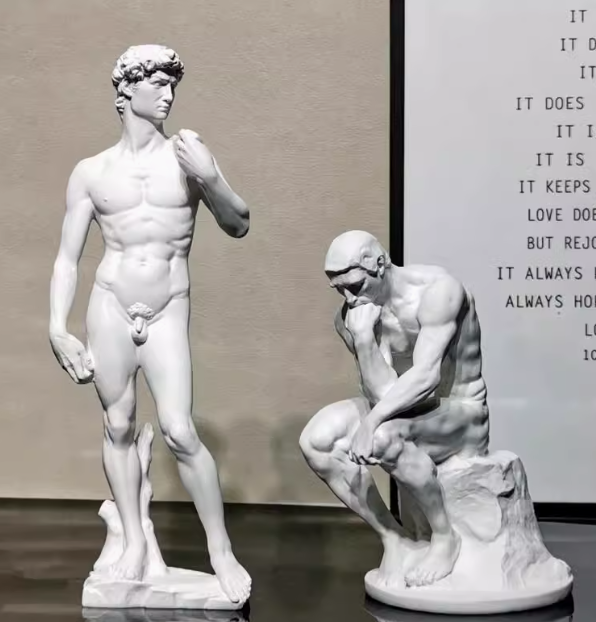

Una fábrica de resinas produce una amplia gama de materiales poliméricos sintéticos que sirven como bloques fundamentales para innumerables aplicaciones industriales y de consumo. Estas instalaciones fabrican diversos tipos de resinas, incluyendo epoxi, poliéster, acrílica, poliuretano y resinas termoplásticas, cada una diseñada para características específicas de desempeño y requisitos de uso final. La función principal de las cosas que se hacen en una fábrica de resinas consiste en crear materiales versátiles que pueden moldearse, fundirse, laminarse o procesarse en productos terminados a través de diversas industrias. La fabricación moderna de resinas incorpora tecnologías avanzadas de síntesis química, sistemas precisos de control de temperatura y monitoreo automatizado de calidad para garantizar especificaciones de producto consistentes. Las características tecnológicas de la producción contemporánea de resinas incluyen procesos de polimerización controlados por computadora, monitoreo en tiempo real de la viscosidad y sistemas especializados de catalizadores que optimizan las propiedades de curado. Estas capacidades de fabricación permiten la producción de resinas con pesos moleculares ajustados, densidades de reticulación y atributos de desempeño personalizados. Las aplicaciones de las cosas que se hacen en una fábrica de resinas abarcan múltiples sectores, incluyendo componentes automotrices, estructuras aeroespaciales, embarcaciones marinas, materiales de construcción, encapsulamiento de electrónicos y fabricación de bienes de consumo. La industria automotriz utiliza compuestos basados en resinas para paneles ligeros de carrocería y refuerzos estructurales, mientras que las aplicaciones aeroespaciales requieren resinas de alto rendimiento para componentes de aeronaves que necesitan relaciones excepcionales entre resistencia y peso. Las aplicaciones en la construcción incluyen recubrimientos arquitectónicos, sistemas de pisos y adhesivos estructurales que ofrecen durabilidad y resistencia climática. La fabricación electrónica depende de resinas especializadas para la producción de placas de circuito, encapsulamiento de componentes y materiales aislantes. La industria marina depende de capas de gel y resinas de fibra de vidrio para cascos y estructuras de cubierta de embarcaciones que resisten entornos salinos agresivos. Las aplicaciones de consumo abarcan artículos decorativos, componentes de muebles y productos recreativos donde el atractivo estético se combina con requisitos funcionales de desempeño.