epoxi transparente para fábrica de artesanías

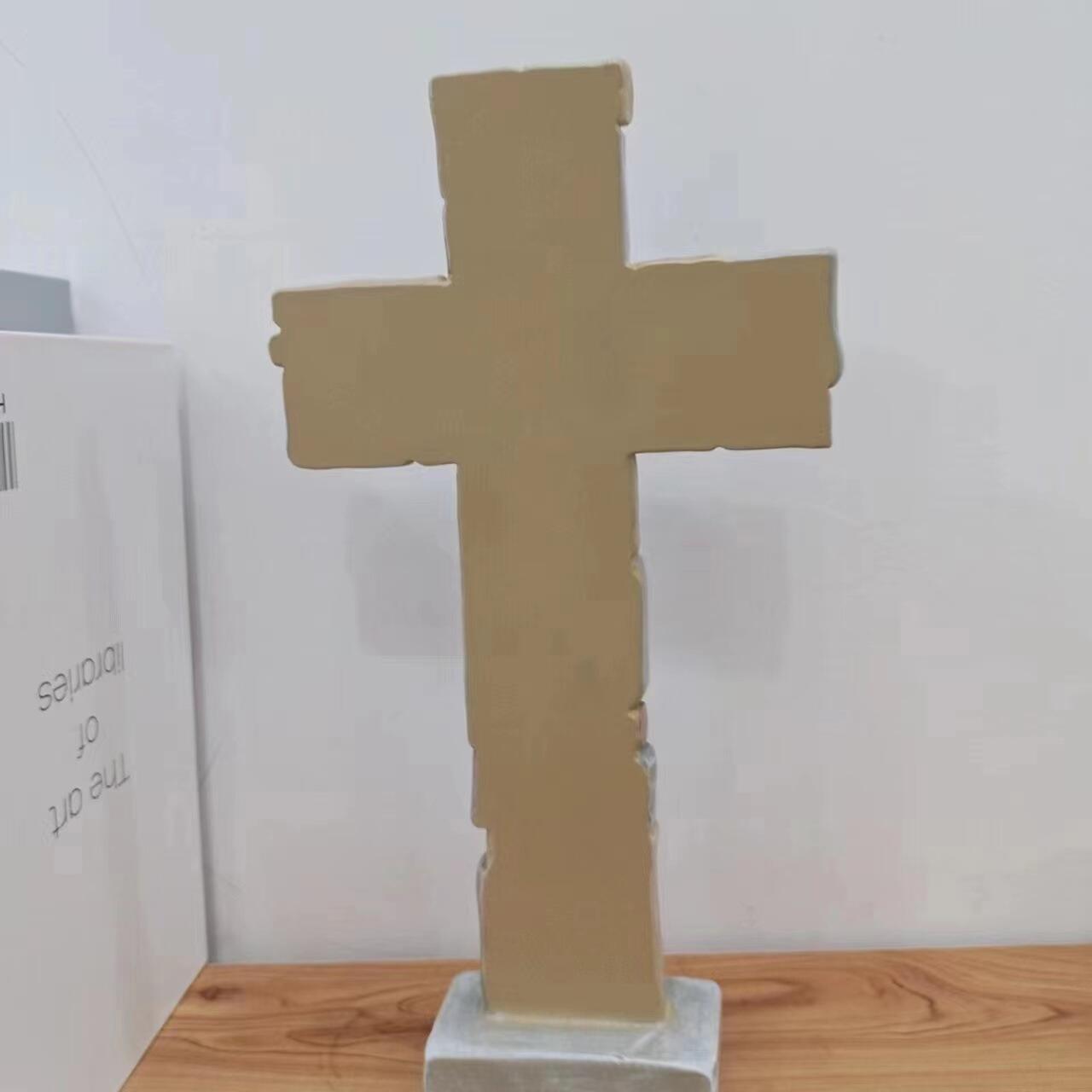

Una fábrica de epoxi transparente para manualidades representa una instalación de fabricación especializada dedicada a la producción de resinas epoxi transparentes de alta calidad, diseñadas específicamente para aplicaciones artísticas y creativas. Estas plantas manufactureras combinan ingeniería química avanzada con sistemas precisos de control de calidad para crear materiales versátiles para manualidades que cumplen con los exigentes requisitos de aficionados, artistas profesionales y productores comerciales de artesanías. La fábrica de epoxi transparente para manualidades opera líneas de producción sofisticadas que transforman componentes químicos básicos en sistemas de resina cristalinos y duraderos mediante procesos de polimerización cuidadosamente controlados. Las instalaciones modernas utilizan equipos avanzados de mezclado, entornos con temperatura controlada y sistemas automáticos de dispensación para garantizar una calidad y rendimiento del producto consistentes. La función principal de una fábrica de epoxi transparente para manualidades consiste en fabricar sistemas epoxi de dos componentes que se curan formando acabados transparentes y similares al vidrio, ideales para diversos proyectos creativos. Estas instalaciones producen normalmente varias viscosidades, desde resinas de colada finas, perfectas para vaciados profundos, hasta formulaciones más espesas adecuadas para aplicaciones superficiales. Laboratorios avanzados de aseguramiento de calidad dentro de cada fábrica de epoxi transparente para manualidades realizan protocolos rigurosos de pruebas, incluyendo mediciones de transparencia, evaluaciones del tiempo de curado y análisis de resistencia de adhesión. La infraestructura tecnológica comprende sistemas informáticos de control por lotes que supervisan las proporciones de mezcla, los perfiles de temperatura y las características de curado durante todos los ciclos de producción. Los controles ambientales mantienen niveles óptimos de humedad y condiciones libres de polvo, esenciales para producir resinas ópticamente claras. Muchas operaciones de fábricas de epoxi transparente para manualidades incorporan prácticas de fabricación sostenible, incluyendo sistemas de recuperación de disolventes y protocolos de minimización de residuos. Las aplicaciones de los productos fabricados en estas instalaciones abarcan numerosos ámbitos creativos, desde la fabricación de joyas y la carpintería hasta esculturas artísticas y recubrimientos decorativos. Los fabricantes profesionales de muebles confían en el epoxi transparente procedente de fábricas especializadas para crear espectaculares mesas de río y efectos de vetas de madera rellenas. Los artistas utilizan estas resinas premium para encapsular elementos naturales, crear obras tridimensionales y producir acabados protectores de alto brillo que preservan los materiales subyacentes mientras realzan su atractivo visual.