coisas legais para fazer com resina na fábrica

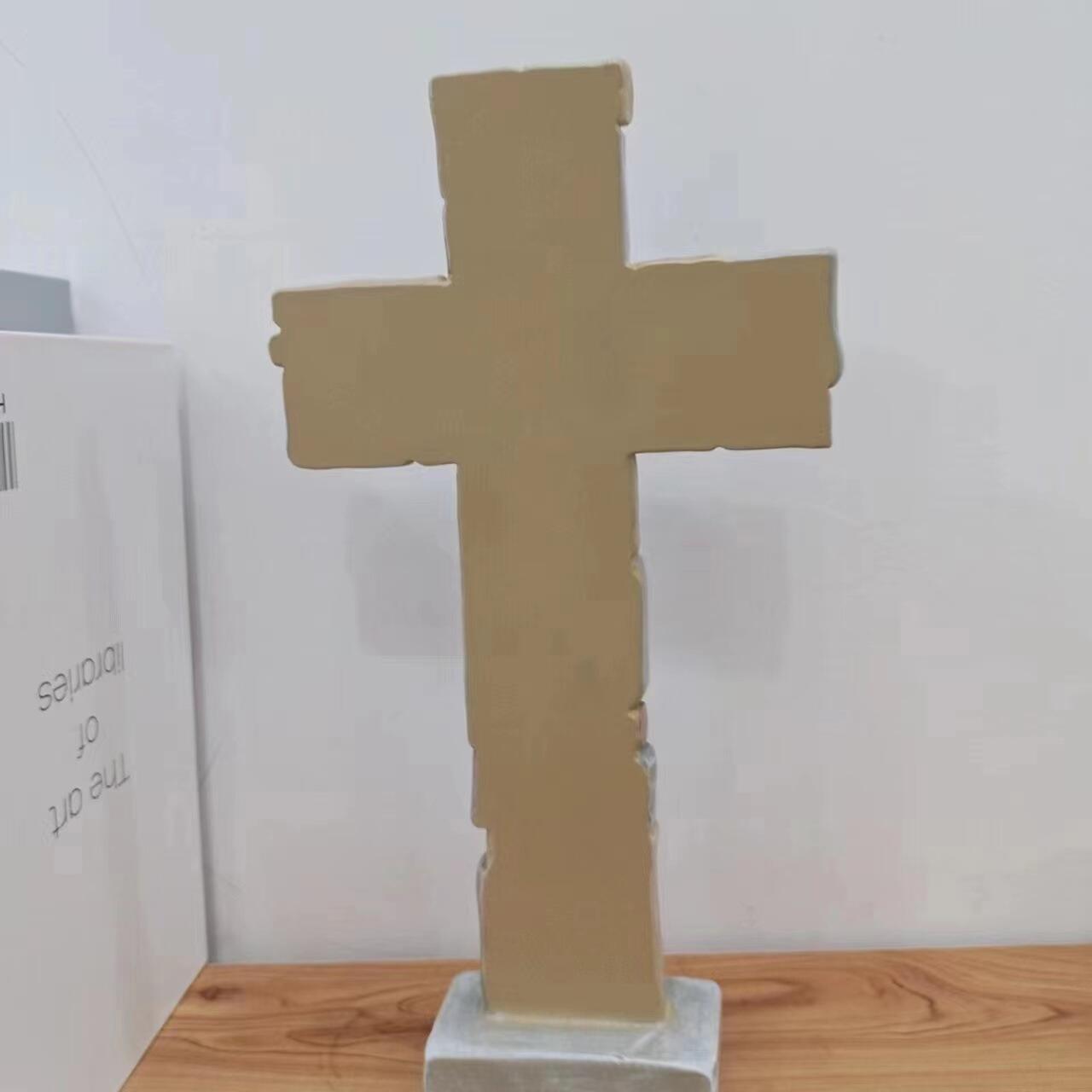

Instalações modernas de fabricação de resinas representam uma abordagem revolucionária para a criação de inúmeros produtos inovadores por meio de tecnologias avançadas de processamento de polímeros. Esses ambientes especializados de produção combinam equipamentos de última geração, engenharia de precisão e práticas sustentáveis de manufatura para transformar materiais brutos de resina em itens extraordinários que cumprem funções tanto funcionais quanto estéticas. Uma fábrica de coisas legais para fazer com resina engloba sistemas sofisticados de moldagem por injeção, aparelhos de moldagem por compressão e câmaras especiais de cura que permitem a criação de diversas categorias de produtos, desde componentes automotivos até artigos decorativos para o lar. A infraestrutura tecnológica dessas instalações inclui sistemas computadorizados de mistura que garantem propriedades consistentes dos materiais, mecanismos automatizados de controle de qualidade que monitoram os parâmetros de produção em tempo real e sistemas avançados de ventilação que mantêm condições ideais de trabalho. As principais funções de uma fábrica de coisas legais para fazer com resina giram em torno da preparação do material, formação do produto, processos de acabamento e protocolos de garantia da qualidade. Os materiais brutos de resina passam por uma preparação cuidadosa envolvendo medição precisa, mistura com aditivos e controle de temperatura para alcançar as características desejadas. O processo de formação utiliza várias técnicas de moldagem conforme as especificações do produto, incluindo moldagem por injeção para geometrias complexas, moldagem por compressão para itens maiores e moldagem rotacional para produtos ocos. Os processos de acabamento incorporam tratamentos superficiais, aplicações de cor e revestimentos protetores que melhoram tanto a aparência quanto a durabilidade. Os protocolos de garantia da qualidade asseguram que cada produto atenda a padrões rigorosos por meio de procedimentos abrangentes de testes. As aplicações dos produtos provenientes de uma fábrica de coisas legais para fazer com resina abrangem diversas indústrias, incluindo fabricação automotiva, materiais de construção, eletrônicos de consumo, dispositivos médicos e artes decorativas. A versatilidade dos materiais de resina permite a personalização de propriedades como resistência, flexibilidade, transparência e resistência química para atender requisitos específicos de aplicação.