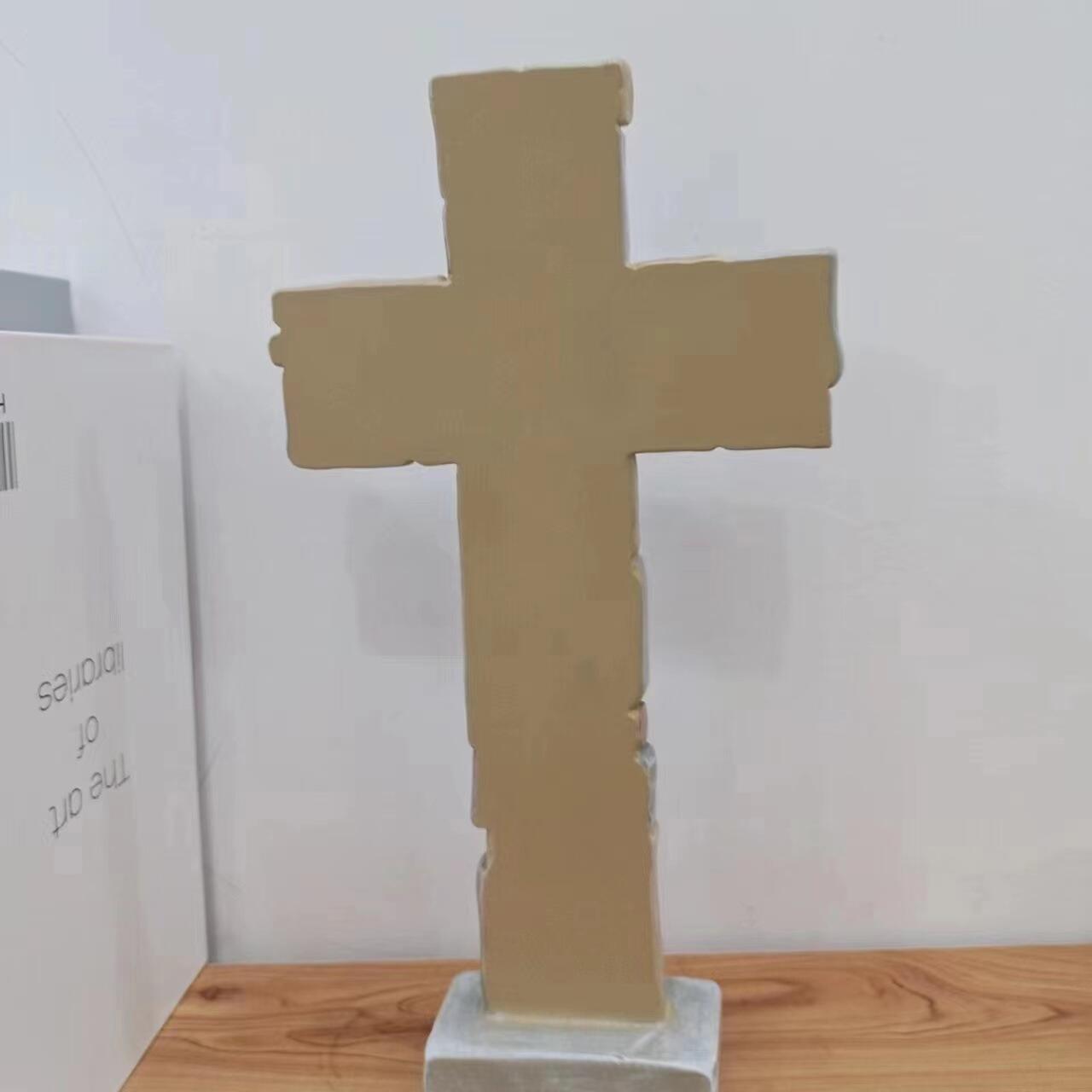

artesão de resina da China

O artesão de resina da China representa um avanço revolucionário em equipamentos de manufatura de precisão projetados especificamente para aplicações artesanais baseadas em resina. Essa maquinaria sofisticada integra tecnologia de ponta com operação amigável ao usuário, proporcionando resultados excepcionais em diversos projetos criativos e industriais. O artesão de resina da China combina sistemas automatizados de mistura, mecanismos de controle de temperatura e capacidades de dosagem precisa para garantir resultados consistentes e de alta qualidade tanto para artesãos amadores quanto para fabricantes profissionais. O equipamento possui controles digitais avançados que permitem aos operadores personalizar as configurações de acordo com requisitos específicos do projeto, incluindo ajustes de viscosidade, modificações no tempo de cura e parâmetros de mistura de cores. Sua construção robusta garante durabilidade e confiabilidade durante ciclos prolongados de produção, enquanto o design compacto o torna adequado para oficinas de diversos tamanhos. O artesão de resina da China incorpora recursos inteligentes de segurança, incluindo sistemas de desligamento automático, controles de ventilação e funções de parada de emergência, para proteger os usuários e manter condições ideais de trabalho. A máquina suporta vários tipos de resina, desde epóxi e poliuretano até formulações especializadas, tornando-a versátil para diversas aplicações. Seu sistema de medição de precisão elimina desperdícios e garante proporções exatas dos materiais, contribuindo para operações economicamente eficientes. O artesão de resina da China também inclui sensores integrados de monitoramento de qualidade que acompanham temperatura, umidade e consistência da mistura, mantendo os padrões do produto. O design modular do equipamento permite fácil manutenção e substituição de componentes, minimizando tempos de inatividade e prolongando a vida útil operacional. Além disso, o artesão de resina da China possui funções de memória programáveis que armazenam configurações frequentemente utilizadas, permitindo uma configuração rápida para projetos repetidos e melhorando a eficiência geral em ambientes de produção.