types de résine pour l'usine d'artisanat

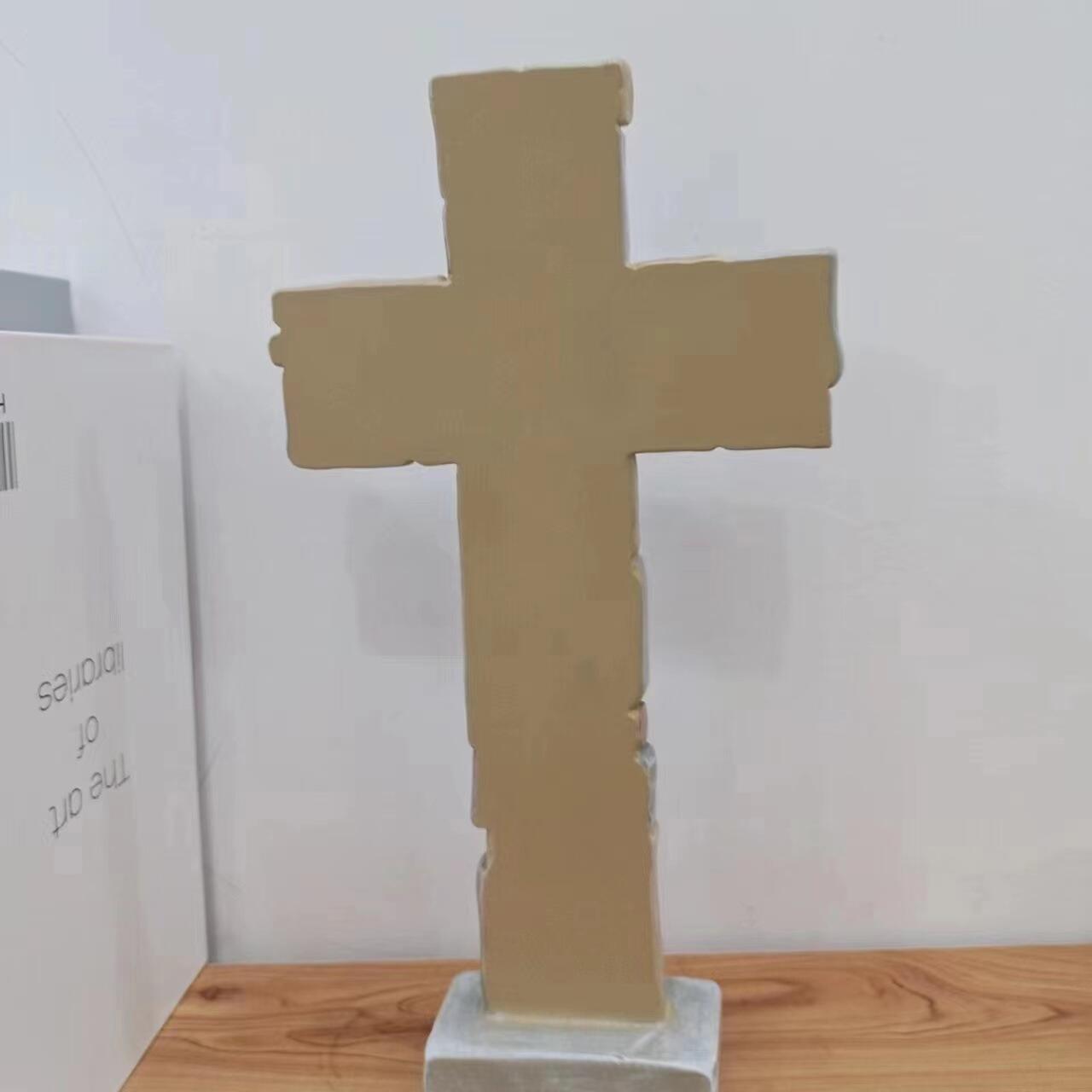

Les types de résine pour les usines d'artisanat comprennent une vaste gamme de matériaux spécialisés conçus pour répondre aux exigences rigoureuses des environnements de fabrication modernes. Ces résines industrielles servent de base à d'innombrables applications artistiques et fonctionnelles, offrant des caractéristiques de performance supérieures qui les distinguent des alternatives grand public standard. Les résines époxy constituent la catégorie la plus polyvalente parmi les types de résine pour les usines d'artisanat, offrant d'excellentes propriétés d'adhérence, une résistance chimique et une résistance mécanique exceptionnelles. Ces systèmes bi-composants durcissent pour former des liaisons incroyablement durables, capables de résister à des températures extrêmes et à des conditions environnementales sévères. Les résines polyuréthane représentent une autre catégorie essentielle parmi les types de résine pour les usines d'artisanat, offrant une flexibilité remarquable et une excellente résistance aux chocs tout en conservant une grande transparence optique. Leur structure moléculaire unique permet des applications nécessitant à la fois solidité et élasticité, ce qui les rend idéales pour les revêtements protecteurs et les moulages flexibles. Les résines polyester offrent des solutions économiques dans l'éventail des types de résine pour les usines d'artisanat, assurant des performances fiables pour les productions à grande échelle. Ces matériaux durcissent rapidement et offrent une bonne stabilité dimensionnelle, ce qui les rend adaptés aux procédés de fabrication en série. Les résines silicones constituent un segment spécialisé des types de résine pour les usines d'artisanat, offrant une résistance thermique inégalée ainsi que des propriétés antiadhésives. Leur biocompatibilité et inertie chimique les rendent indispensables pour les dispositifs médicaux et les applications alimentaires. Les résines acryliques complètent les principaux types de résine pour les usines d'artisanat, offrant une excellente résistance aux UV et une stabilité des couleurs pour les applications extérieures. Les caractéristiques technologiques inhérentes à ces types de résine pour les usines d'artisanat incluent un contrôle précis de la viscosité, des temps de durcissement prévisibles et des lots de qualité constante, garantissant des résultats reproductibles au fil des cycles de production. Des formulations avancées incorporent des agents ignifuges, des antimicrobiens et des charges spéciales afin d'améliorer certaines caractéristiques de performance. Les applications s'étendent aux composants automobiles, aux éléments architecturaux, aux objets décoratifs, aux équipements de protection et aux outillages industriels.