polyrésine statuée

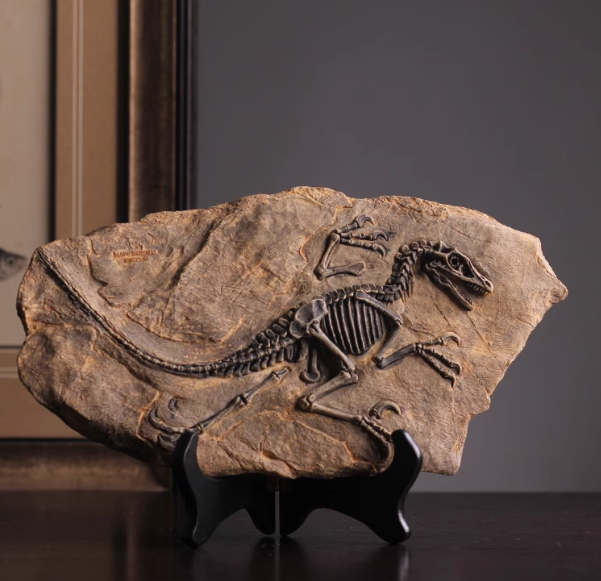

La statue en polyrésine représente un matériau révolutionnaire dans l'industrie des arts décoratifs, combinant des polymères synthétiques à des charges minérales naturelles pour créer un support exceptionnel pour les œuvres sculpturales. Ce matériau composite innovant a transformé la manière dont artistes, fabricants et collectionneurs abordent la création et l'exposition d'art tridimensionnel. La statue en polyrésine offre une polyvalence remarquable, permettant la production de détails complexes qui seraient difficiles, voire impossibles, à réaliser avec des matériaux traditionnels tels que le bronze, le marbre ou la céramique. Le procédé de fabrication consiste à mélanger une résine liquide avec des poudres minérales, créant ainsi une substance malléable qui durcit pour former un produit fini durable et léger. Cette avancée technologique permet la production en série de pièces décoratives de haute qualité tout en préservant l'intégrité artistique et l'attrait visuel. La composition du matériau assure une excellente stabilité dimensionnelle, empêchant toute déformation ou fissuration dans des conditions environnementales normales. Les sculptures en polyrésine peuvent reproduire l'apparence de matériaux naturels coûteux à une fraction du prix, rendant l'art accessible à un public plus large. Le matériau accepte divers traitements de surface, notamment la peinture, la teinture et le texturage, permettant aux artistes d'obtenir une grande variété d'effets esthétiques. Sa nature non poreuse facilite le nettoyage et l'entretien, qui se limitent à un simple dépoussiérage ou à un lavage doux. Les applications de la statue en polyrésine s'étendent à la décoration résidentielle, aux présentoirs commerciaux, aux établissements éducatifs, aux lieux religieux et aux installations extérieures. Les musées utilisent fréquemment ce matériau pour produire des répliques, protégeant ainsi les artefacts originaux tout en offrant une valeur pédagogique. Les centres jardiniers exposent des sculptures extérieures résistantes aux intempéries, tandis que les designers d'intérieur intègrent des pièces élégantes destinées à l'intérieur. La malléabilité du matériau permet la reproduction de chefs-d'œuvre classiques, de créations contemporaines et d'œuvres sur commande personnalisées. Les usines de fabrication peuvent produire des séries importantes avec une qualité constante, assurant l'uniformité dans les applications commerciales tout en conservant l'aspect artisanal recherché par les clients.