petite usine d'artisanat en résine

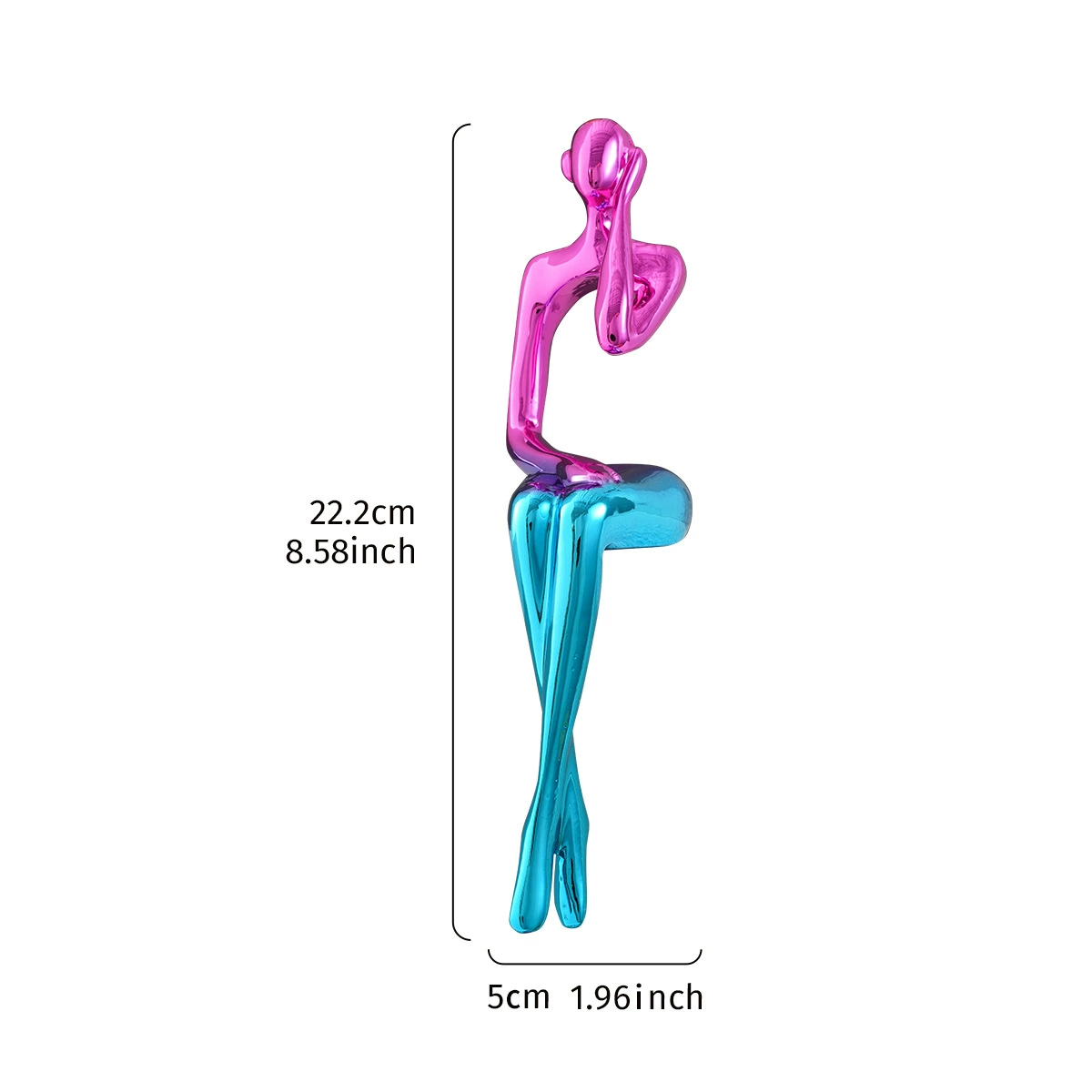

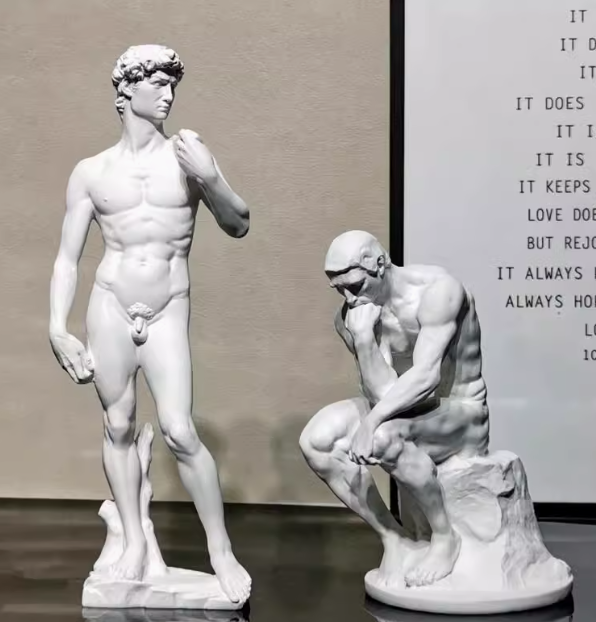

Une petite usine d'artisanat en résine représente un site de fabrication spécialisé conçu pour produire des articles décoratifs et fonctionnels de haute qualité à l'aide de différents types de matériaux résineux. Ces unités de production compactes se concentrent sur la création de pièces artistiques sur mesure, de produits promotionnels, de composants de bijoux, d'articles de décoration intérieure et de prototypes industriels grâce à des techniques avancées de moulage par résine. La petite usine d'artisanat en résine fonctionne avec des équipements de moulage de précision, des systèmes de durcissement contrôlés en température et des mesures de contrôle qualité garantissant des normes de production constantes. Les fonctions principales d'une petite usine d'artisanat en résine comprennent la consultation en conception, la création de moules, le mélange des matériaux, les procédés de coulage, les finitions et les services d'emballage. Ces installations traitent généralement aussi bien les résines époxy que les résines polyuréthane, permettant ainsi diverses applications produit dans plusieurs secteurs industriels. Les caractéristiques technologiques incluent des systèmes automatisés de mélange garantissant des rapports précis entre résine et durcisseur, des chambres sous vide pour éliminer les bulles d'air et des postes de durcissement UV destinés à des types de résine spécifiques. Les installations modernes de petites usines d'artisanat en résine intègrent des outils numériques de conception, des capacités d'impression 3D pour la réalisation rapide de prototypes et des systèmes informatisés de gestion des stocks. Les applications s'étendent à de nombreux secteurs, notamment les composants automobiles, les éléments architecturaux, les sculptures artistiques, les cadeaux personnalisés, les récompenses d'entreprise et les maquettes pédagogiques. Les considérations environnementales poussent de nombreuses petites usines d'artisanat en résine à adopter des formulations écologiques et des protocoles de réduction des déchets. Les protocoles d'assurance qualité garantissent que chaque produit respecte les normes de durabilité, d'esthétique et de sécurité avant expédition. La souplesse inhérente aux opérations de petites usines d'artisanat en résine permet une adaptation rapide aux tendances du marché et aux spécifications clients, ce qui en fait des partenaires idéaux pour les entreprises ayant besoin de produits résine spécialisés en petites quantités, sans compromettre la qualité ni les délais de livraison.