Polyresin, a durable synthetic resin, plays a significant role in the toy manufacturing industry due to its excellent properties. It is predominantly used in creating collectible figurines, action figures, and a variety of decorative items. This material is favored not only for its robustness but also for its ability to be intricately molded, allowing for detailed designs and high-quality finishes. The application of polyresin in these toys has revolutionized production by ensuring consistency in texture and the ability to apply varied and intricate finishes, including metallic and painted surfaces.

The increasing adoption of polyresin by toy manufacturers is a testament to its efficiency and superior product quality. Its versatility in moldability and finishing enables the production of toys that meet both aesthetic and functional demands. Moreover, the ability to mold polyresin into complex shapes with intricate details makes it ideal for producing personalized and unique toy designs. This, combined with the ability to withstand diverse environmental conditions, makes polyresin a preferred choice for companies striving to meet high-quality standards in toy production.

High Durability and Strength of Polyresin

Impact-resistant and long-lasting material

Polyresin is renowned for its exceptional toughness, becoming a preferred material due to its resistance to breakage and wear. Toys crafted from polyresin can withstand significant impacts without damage, as demonstrated by numerous durability tests. This makes them long-lasting and ideal for active play environments where rough handling is common. With its impressive attributes, polyresin ensures that toys remain intact and functional over time, making it an attractive choice for both manufacturers and consumers seeking durable toy materials.

Ideal for collectible and decorative toys

Collectible and decorative toys demand materials that can withstand the test of time without fading or chipping, a domain where polyresin excels. High-end decorative toys often use polyresin because it maintains vibrant colors and exquisite details over prolonged periods. Additionally, statistics indicate that collectibles made from polyresin hold their value more effectively than those fabricated from alternative materials. This durability and retention of quality significantly contribute to the desirability and engagement of collectors, ensuring that polyresin remains a staple in collectible toy manufacturing.

Excellent Detailing and Customization

Allows for intricate designs and textures

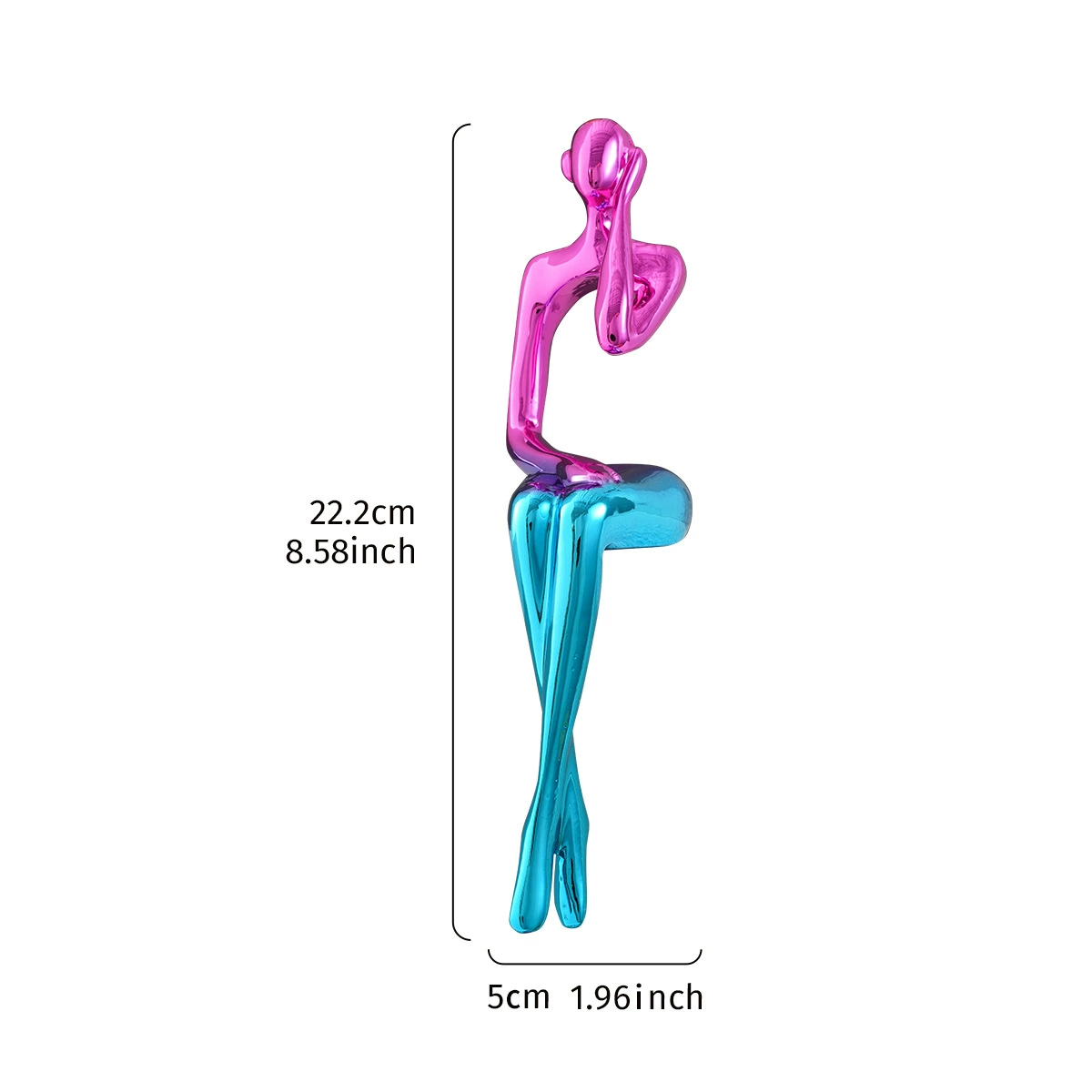

Polyresin is renowned for its capability to be molded into complex shapes and intricate designs that traditional materials might not accommodate. This flexibility allows artisans to craft unique products with detailed textures, resembling natural materials, which significantly enhances a toy's visual appeal. For example, polyresin can be used to create toy surfaces that mimic wood grains or stone surfaces. The precision achievable with this material provides manufacturers with the ability to produce toys that stand out in a competitive market through intricate designs and customization.

Can be painted, molded, or finished to mimic other materials

Polyresin toys can be painted and finished to create diverse aesthetics, simulating the appearance of other materials like wood or stone. Techniques such as molding allow for the incorporation of features like movable parts or unique patterns, further expanding design possibilities. This versatility provides manufacturers with the ability to cater to varied consumer tastes, by offering toys that can mimic desired materials at a fraction of the cost. Ultimately, the capability to easily paint and customize polyresin makes it a favored choice for creating personalized and visually compelling toys.

Cost-Effective and Efficient Production

Lower Cost Than Metal or Porcelain

Polyresin offers a cost-effective alternative to materials like metal or porcelain, significantly reducing production expenses. Its affordability makes it an attractive option for manufacturers aiming to allocate more resources towards design innovation and marketing efforts rather than spending heavily on raw materials. Industry studies reveal that producing toys with polyresin costs only a fraction compared to using metals, thereby allowing companies to offer competitive pricing and access wider consumer markets. This cost-benefit enhances the appeal of polyresin in toy manufacturing, making it a preferred choice for many businesses.

Easy to Mass-Produce with Consistent Quality

Polyresin's properties make it easy to mass-produce while maintaining consistent quality. Efficient molding processes allow manufacturers to streamline production, ensuring each toy is uniformly crafted with high precision. Quality control is simpler and less labor-intensive compared to traditional manufacturing methods, resulting in reliable output. This efficiency enables companies to respond rapidly to market demands, reducing production times significantly. The streamlined nature of polyresin production allows for timely introductions of new designs and quicker replenishment of popular items, making it an ideal choice for mass-market toy production.

Lightweight Yet Sturdy

Easier to handle and transport compared to heavier materials

The lightweight nature of polyresin makes it a practical choice for both manufacturers and consumers. It simplifies handling during the production process, allowing workers to move and manage materials with ease. This feature also benefits consumers, particularly parents who value toys that can be easily managed by children or moved around the home. Additionally, retailers selling polyresin products face fewer logistical challenges and reduced labor costs due to its lighter weight. By offering the user-friendly attributes of lightweight materials, polyresin stands out in a market looking for practical, efficient options.

Reduces shipping costs for manufacturers

One of the significant advantages of polyresin's lightweight property is the reduction in shipping expenses. Lower weight means that manufacturers can ship larger quantities of toys at once, effectively reducing the overall distribution costs. Moreover, streamlined logistics allow producers to manage their inventory and supply chains more efficiently, enhancing profit margins. According to logistics data, polyresin toys enable manufacturers to optimize the entire shipping process, ensuring products are delivered swiftly and cost-effectively. By minimizing shipping costs, companies can offer competitive pricing and reach a broader market.

Heat and Chemical Resistance

Withstands mild heat and exposure to chemicals

Polyresin's impressive resistance to mild heat makes it highly suitable for outdoor toys. Its resilience ensures that toys exposed to the sun remain intact without warping or melting. Additionally, polyresin toys can be safely cleaned using mild detergents without compromising their quality. Experts confirm that polyresin resists damage from various chemicals, which significantly prolongs the lifespan of these toys. This characteristic is crucial for parents and retailers, as it ensures the safety and durability of toys despite regular cleaning or exposure to the elements.

Ensures toys remain in good condition over time

The inherent longevity of polyresin contributes to toys maintaining both their visual appeal and structural integrity for many years. Consumers frequently express satisfaction with the durability of polyresin toys, which has fostered strong brand loyalty. Reviews from users consistently show that these toys retain their appearance better than those made from other materials, such as plastic. This durability ensures that toys not only last longer but also preserve their aesthetic qualities, enhancing customer satisfaction and repeat purchases.

Eco-Friendly Options Available

Some formulations use recycled materials

Polyresin presents an eco-friendly solution as many of its formulations are crafted using recycled materials. This approach not only caters to environmentally conscious consumers but also aligns with the increasing sustainability trends prevalent in the toy industry. Manufacturers that actively promote the use of recycled inputs report notable reductions in carbon footprints, according to environmental studies. By integrating recycled components, polyresin becomes an appealing choice for those seeking eco-friendly toys.

A more sustainable choice compared to plastics

When compared to traditional plastics, polyresin offers a more sustainable alternative due to its biodegradable properties under specific conditions. This trait addresses the growing consumer demand for eco-friendly products, as individuals increasingly prefer materials that minimize environmental impact. Research consistently shows that brands committed to sustainability receive heightened trust and loyalty from consumers. Polyresin's ability to break down more readily than conventional plastics contributes significantly to reducing the environmental footprint of toys crafted from this material.

Conclusion

In summary, polyresin offers numerous advantages for toy manufacturing, setting it apart as a durable and detail-oriented material. Its ability to be intricately molded allows manufacturers to create toys with exceptional detail and consistent texture. Polyresin is not only sturdy but also versatile, compatible with multiple finishes, making it ideal for both collectible and functional toys. These attributes make polyresin an excellent choice for manufacturers looking to enhance their product offerings in the competitive toy industry. By embracing polyresin, businesses can capitalize on its durability, detail, and cost-effectiveness to create high-quality toys that appeal to a wide range of consumers.

FAQs

What is polyresin?

Polyresin is a durable synthetic resin known for its robustness, versatility in molding, and ability to create intricate designs and high-quality finishes.

Why is polyresin used in toy manufacturing?

Polyresin is favored in toy manufacturing due to its durability, intricate molding capabilities, cost-effectiveness, and ability to withstand environmental conditions.

Are polyresin toys eco-friendly?

Yes, many polyresin formulations use recycled materials and are more biodegradable compared to traditional plastics, offering a more sustainable option.

Can polyresin withstand heat and chemicals?

Polyresin can withstand mild heat and exposure to chemicals, making it suitable for outdoor toys and ensuring durability over time.

How does polyresin compare to materials like metal or porcelain?

Polyresin is more cost-effective, lighter, easier to mass-produce, and offers comparable durability and quality as materials like metal or porcelain.