poly resin figurines manufacturer

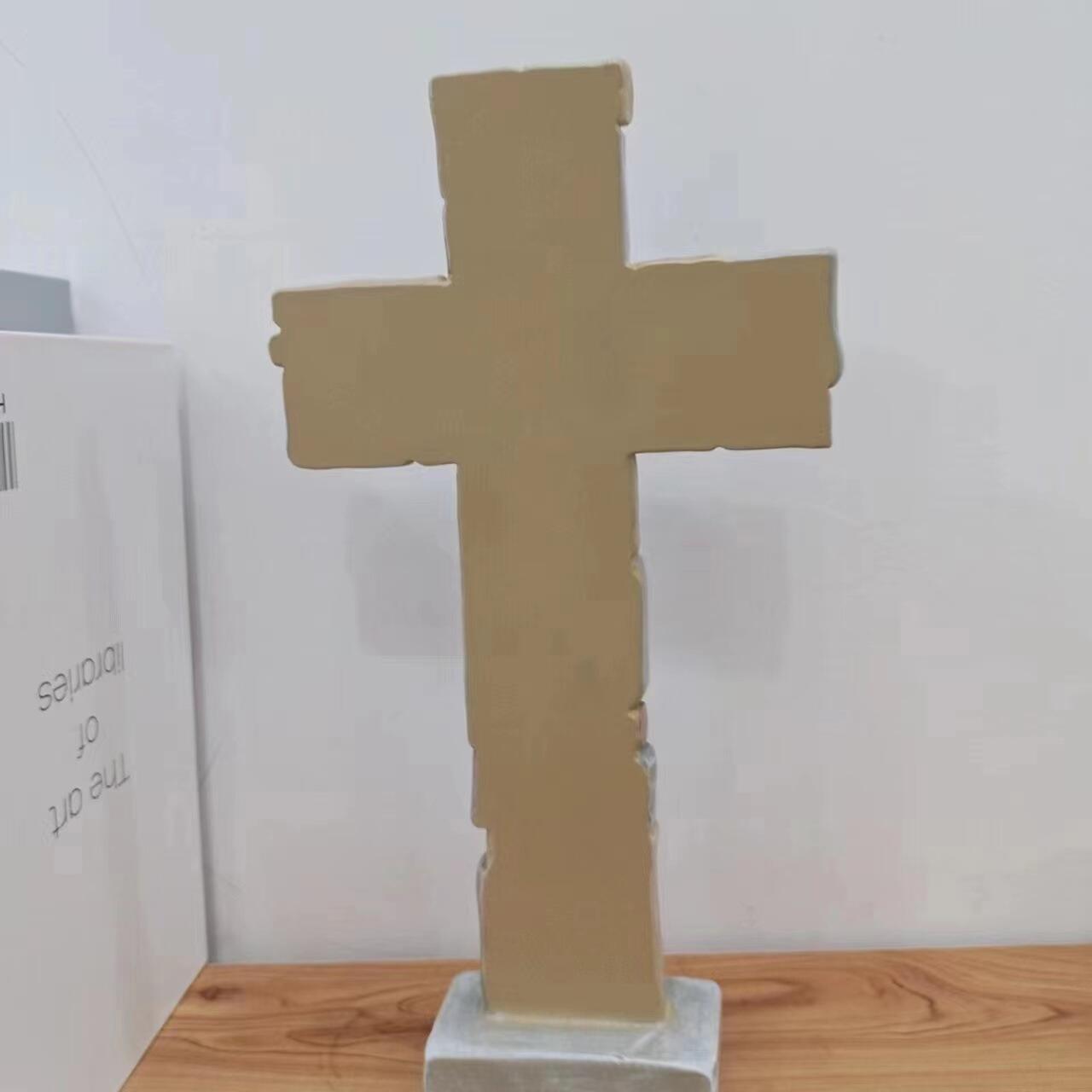

A poly resin figurines manufacturer specializes in creating detailed collectible figures and decorative items using polyresin, a versatile synthetic material that combines the best properties of plastic and ceramic. These manufacturers serve diverse markets including entertainment collectibles, home décor, promotional items, and artistic sculptures. The primary function of a poly resin figurines manufacturer involves transforming creative designs into tangible three-dimensional products through sophisticated molding and finishing processes. Modern poly resin figurines manufacturers utilize advanced casting techniques, precision molding equipment, and multi-stage production workflows to ensure consistent quality and intricate detail reproduction. The technological backbone includes computer-aided design systems, automated mixing equipment for resin compounds, temperature-controlled curing ovens, and specialized painting booths equipped with airbrush systems. Quality control measures encompass dimensional accuracy testing, surface finish inspection, and durability assessments. Applications span multiple industries, from licensed character merchandise for major entertainment franchises to architectural model components and promotional corporate gifts. Museums and educational institutions frequently collaborate with poly resin figurines manufacturers to create replica artifacts and interactive display pieces. The manufacturing process begins with master sculpting, followed by silicone mold creation, resin casting, curing, demolding, surface preparation, painting, and final assembly. Advanced manufacturers incorporate sustainable practices, utilizing eco-friendly resin formulations and implementing waste reduction protocols. Digital printing technologies enable photorealistic surface details, while hand-painting techniques provide artistic authenticity. Many poly resin figurines manufacturers offer custom design services, prototyping capabilities, and small-batch production options to accommodate specialized client requirements. The industry serves collectors, retailers, theme parks, movie studios, game developers, and individual artists seeking professional-grade figurine production.