epoxy resin small projects factory

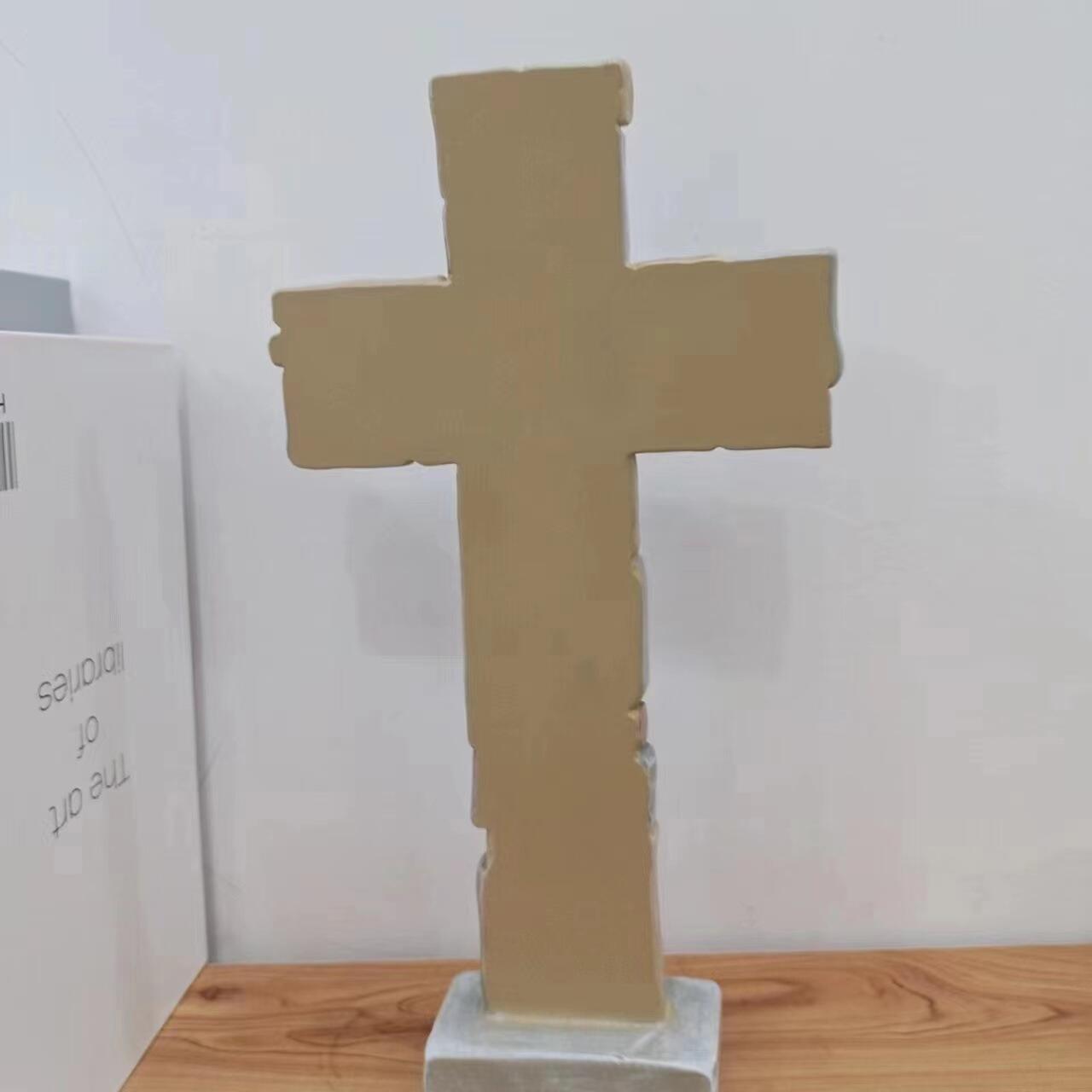

An epoxy resin small projects factory represents a specialized manufacturing facility designed to produce custom resin-based items for diverse applications ranging from artistic creations to functional components. These facilities combine traditional craftsmanship with modern production techniques to deliver high-quality epoxy resin products that meet specific customer requirements. The epoxy resin small projects factory operates as a comprehensive solution provider, offering services from initial design consultation through final product delivery. The main functions of an epoxy resin small projects factory encompass product design, mold creation, casting operations, finishing processes, and quality control. These facilities utilize advanced mixing systems that ensure precise epoxy-to-hardener ratios, eliminating common issues like incomplete curing or surface defects. Temperature-controlled environments maintain optimal working conditions for consistent results across all production batches. The technological features include state-of-the-art vacuum chambers that remove air bubbles during the casting process, resulting in crystal-clear finished products. Digital measuring systems guarantee accurate material proportions, while automated mixing equipment ensures uniform distribution of additives such as pigments, glitter, or embedded objects. Many factories incorporate UV-resistant formulations and advanced curing techniques that accelerate production timelines without compromising quality. Applications for products from an epoxy resin small projects factory span numerous industries and personal uses. Decorative items include custom jewelry, artistic sculptures, and home décor pieces that showcase the material's versatility. Functional applications encompass protective coatings, electronic component encasements, and specialized tools for various trades. The factory environment enables mass production of popular items while maintaining the flexibility to handle unique one-off projects. Quality assurance protocols ensure each item meets durability standards, with many products featuring scratch-resistant surfaces and long-lasting color stability that maintains appearance over extended periods.